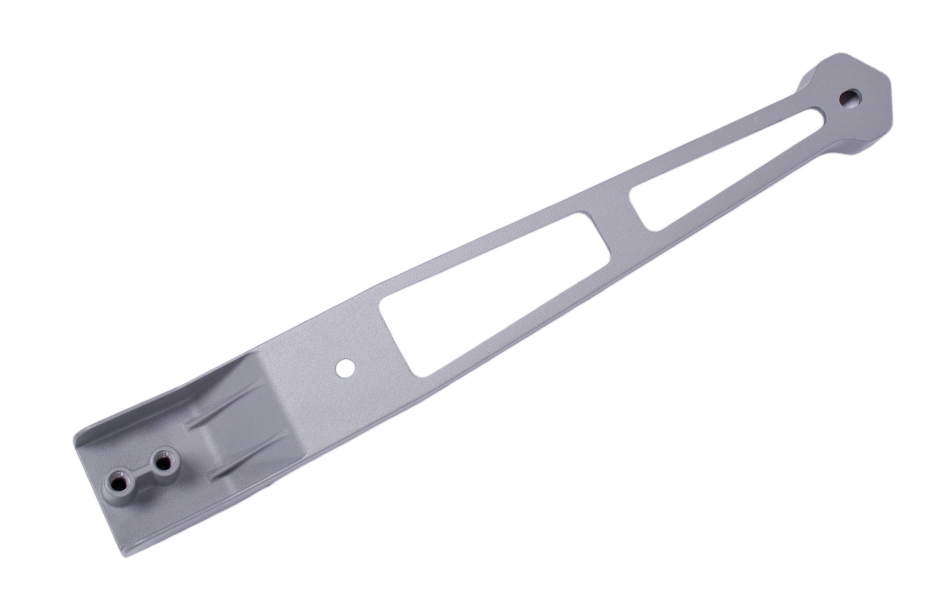

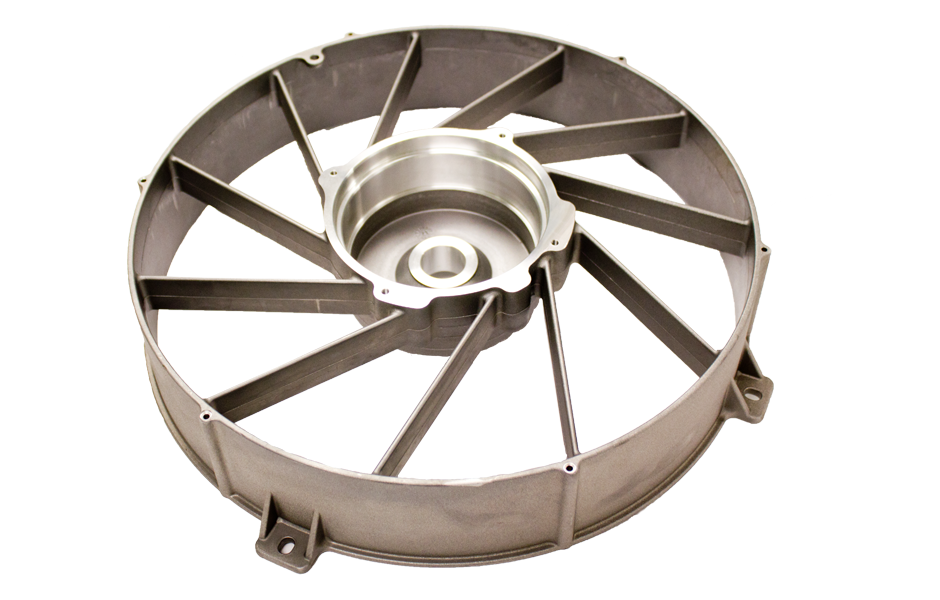

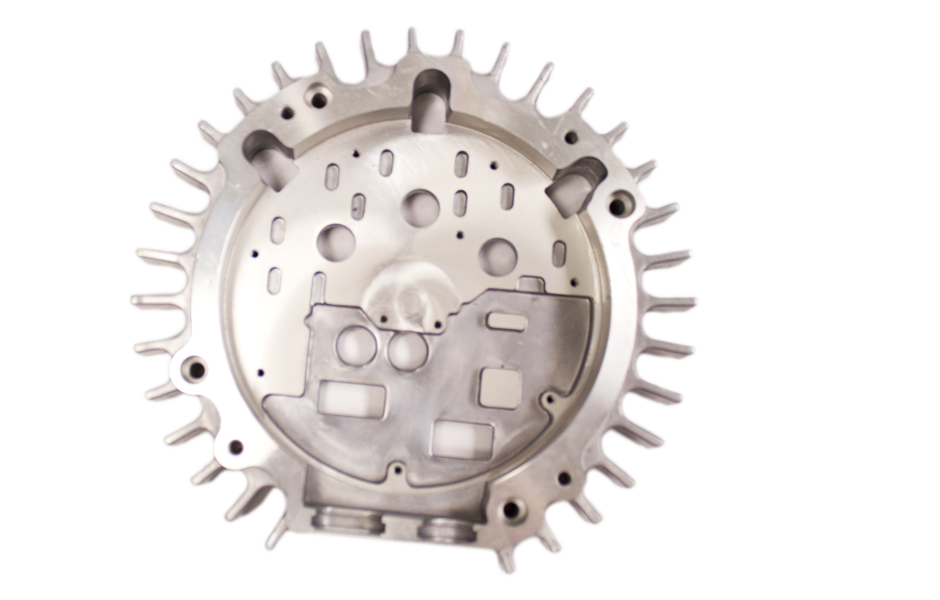

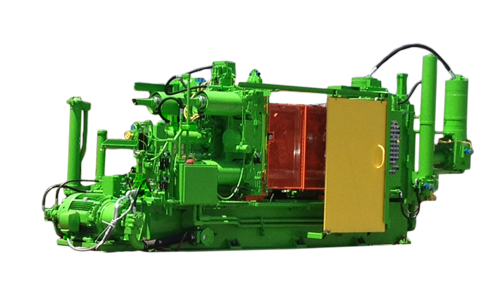

Aluminum Die Casting

Serv-All specializes in die casting aluminum components and can accommodate jobs of all sizes with both low and high volume production programs. We believe that our customers deserve the best, so we integrate numerous services to provide you with the perfect tool and casting to match your needs. We utilize process monitoring, robotics, flow simulation, and tool maintenance programs to extend tool life, reduce cycle times, reduce costs, and provide high-quality die castings for our customers.

Advantages of Aluminum Die Casting

Aluminum is the most commonly cast non-ferrous metal in the world because it is extremely cost effective. Two of the most significant benefits of aluminum die casting are that it creates lighter parts and that it can withstand the highest operating temperatures of all die cast alloys.

Aluminum Alloy Characteristics

- Lightweight

- Excellent strength and hardness

- High operating temperatures

- Outstanding corrosion resistance

- Full recyclability

- Great finishing characteristics

- Excellent EMI and RFI shielding properties

- Good stiffness and strength-to-weight ratio

- Excellent thermal and electrical conductivity

Aluminum Casting Alloys

Our Alloys Include: Aluminum 360, 380, 383 and 413

Aluminum Surface Finishing

Serv-All will manage customer finishing requirements to ensure parts meet specifications in a timely and cost-effective manner.

Our aluminum surface finishes include (but are not limited to):

- Powder coating

- Wet paint

- E-coat

- Anodizing

- Chromating

- Sealant impregnation

- Electroless nickel plating

- Chrome

- Vacuum metalizing

- Silk screening and stenciling

- Surface conditioning (shot and bead blasting)

Aluminum Mold Flow Testing

Serv-All has the ability to utilize simulation technology to optimize tool design and aluminum casting quality. Simulation capabilities provide a better understanding of aluminum injection mold filling, high pressure aluminum die casting, solidification, mechanical properties, thermal stresses, and distortions.

Prototyping Aluminum Parts

Serv-All can provide components in prototyping and low-volume production quantities using a variety of different methods, such as:

- CNC machining

- Plaster injection mold castings

- Direct Metal Laser Sintering (DMLS)

- P-20 tooling

Gallery