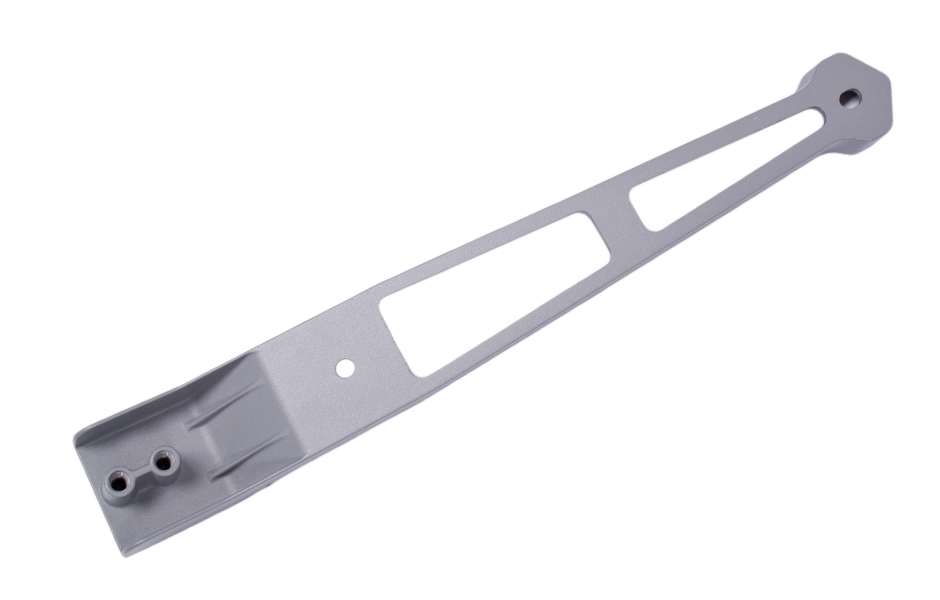

Innovative Design and Build

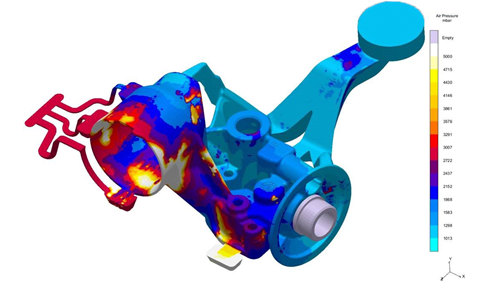

Serv-All has been designing & building die cast tools since 1945. We understand that a tool must be built to the highest standards to consistently hold dimensional tolerances, manufacturing rates, and have predictable tool life. Our in-house engineering staff provides expert consultation on the design, tooling, and production. From small to large, single cavity to multi-cavity, our design capabilities are world-class. Careful oversight, coupled with effective and timely customer communication, assure that all aspects of the tooling, quality requirements, and production result in a sound, repeatable processes.

Innovative Design solutions:

- Reduce retooling frequency with tools built from only the best certified tool steel grade

- Minimize downtime with low-maintenance tooling

- Extended tool life with surface coatings

- Eliminate costly secondary operations, such as deburring, trimming, drilling, and machining

- Reduce tooling lead times for fast delivery

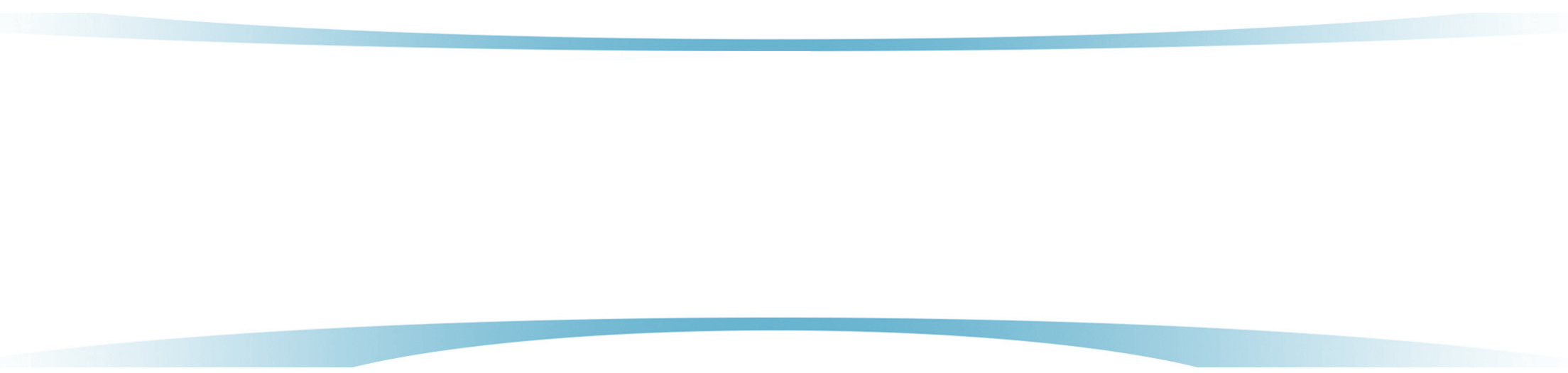

- Use Mold flow analysis software and techniques to give the part density and optimum fill because of gating, venting, and overflow placement

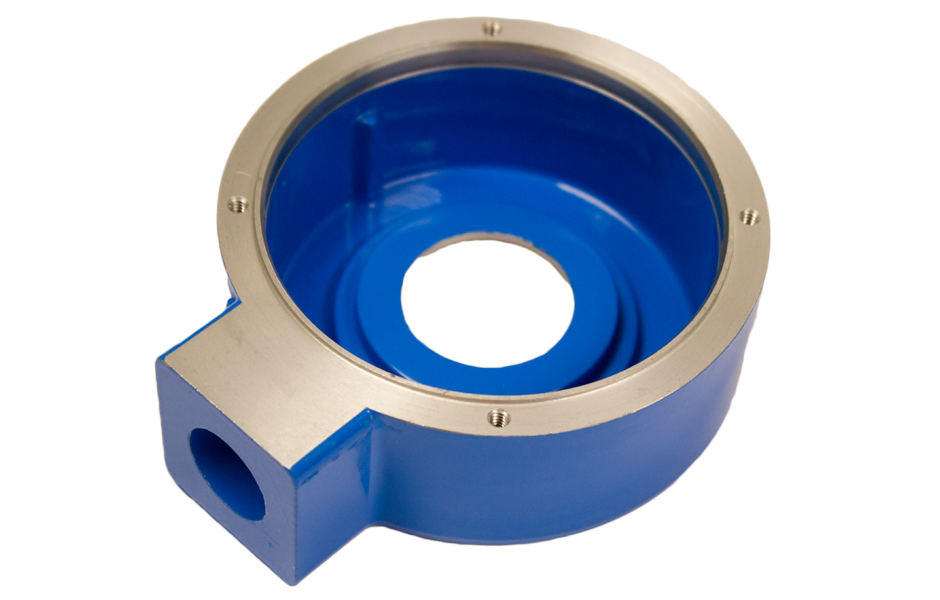

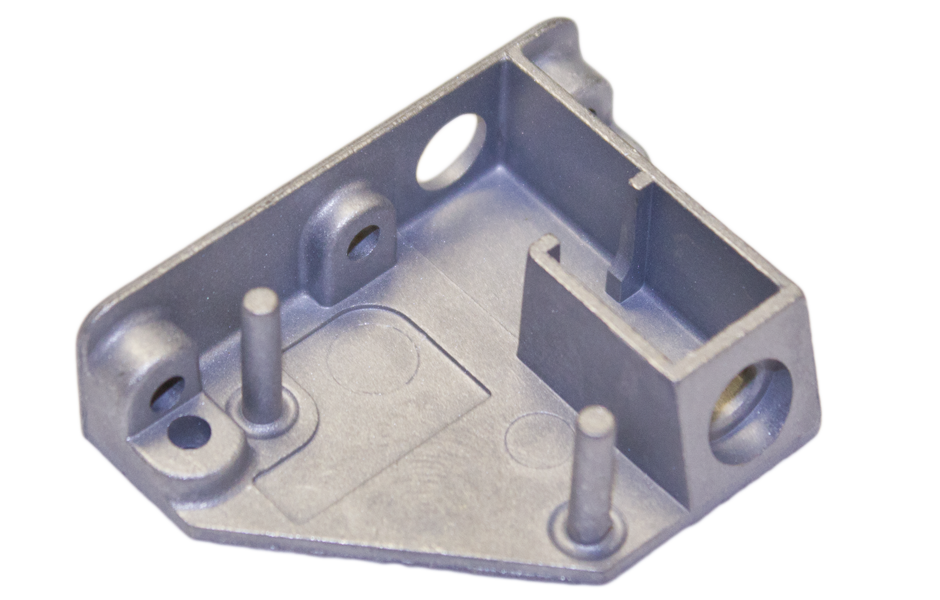

Production and Repair

With an in-house tool room and fully stocked mold and die component inventory, we provide short lead times on repairs. We assure continuous, high volume, trouble-free molding through innovative validation.