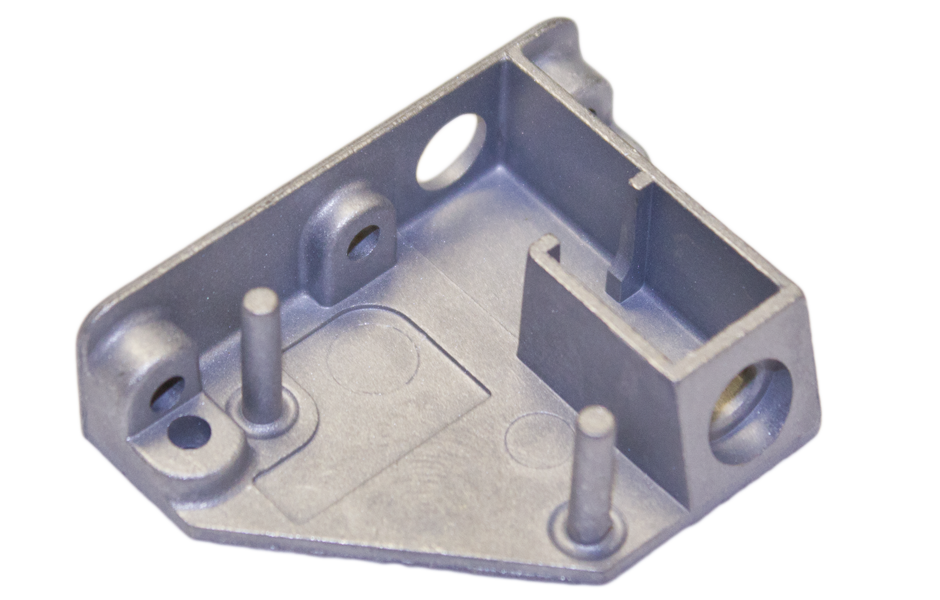

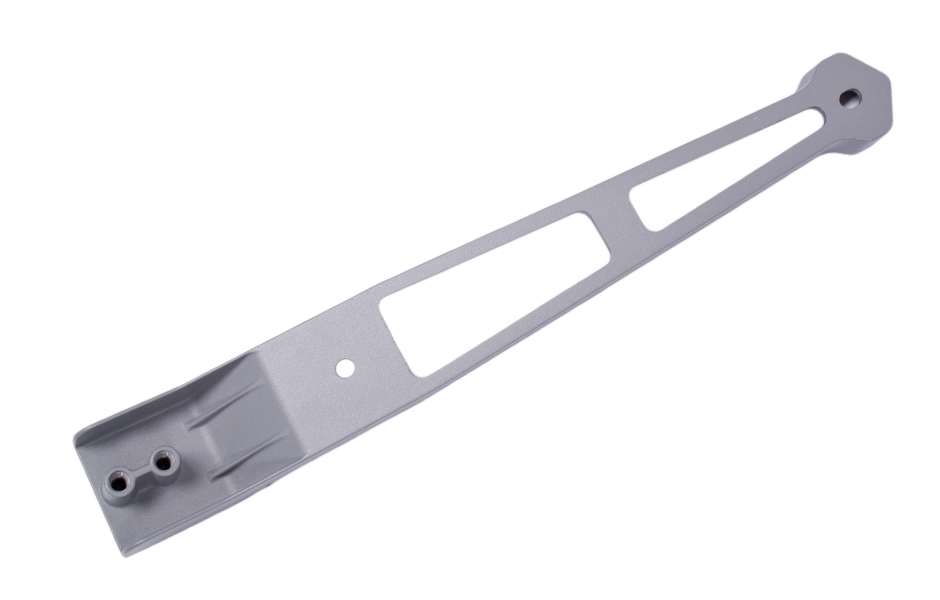

Machining

We offer in-house machining as a complement to our die casting services. Depending on your requirements, we can customize a machining process to meet your specifications and budget.

Our capabilities include:

- CNC Machining: Vertical, horizontal, drill and tap, and turning are preformed in-house to reduce lead-times and maximize quality.

- Conventional Machining: Dedicated single to multi-station centers for drilling, tapping, reaming & milling. Custom built machining centers can perform a variety of machining options that can turn into cost savings.

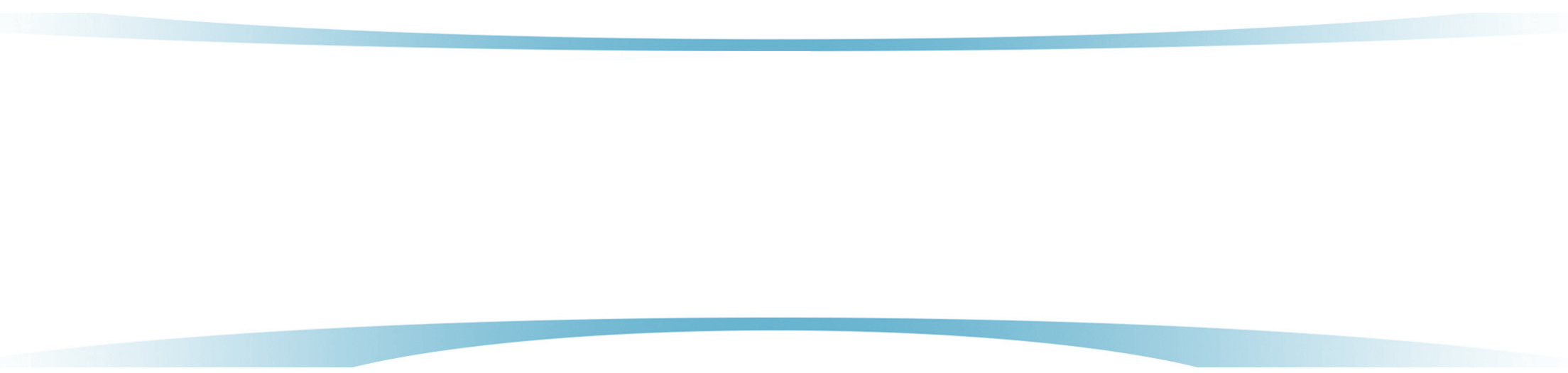

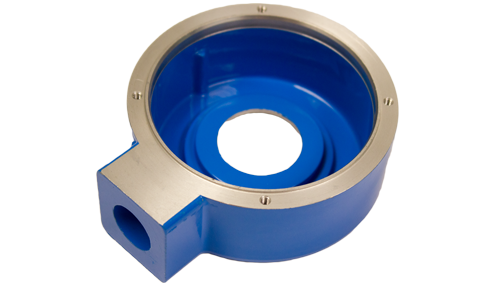

Metal Finishing

Serv-All has a long list of different types of metal finishes offered and pride ourselves on our consistent, repeatable finishes.

Metal finishing options offered by Serv-All are (but are not limited to):

- Vibratory deburring

- Shot blasting / Wheel blasting

- Polishing

- Powder coating

- Wet paint

- E-coat

- Anodizing

- Chromating

- Sealant impregnation

- Electroless nickel

- Chrome

- Vacuum metalizing

- Silk screening and stenciling

- Surface conditioning (shot and bead blasting)

Assembly/ Packaging

From start to finish, Serv-All can provide product assembly and packaging. With all steps of the manufacturing process, we can provide a cost-effective finished product with special attention to quality and production deadlines. Our talented crew can take care of all your product assembly needs from sourcing components to shipping directly to the end user.