Commitment to Quality

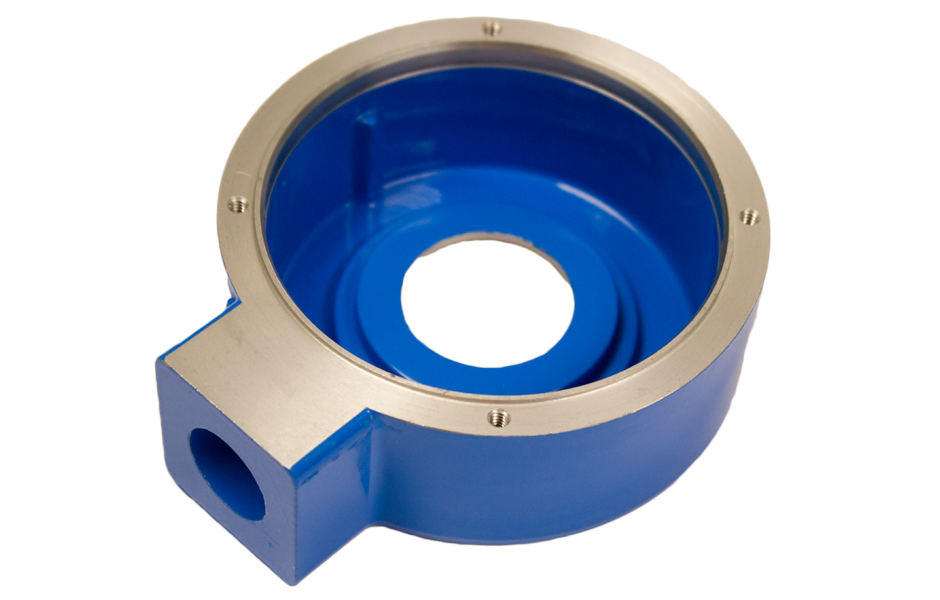

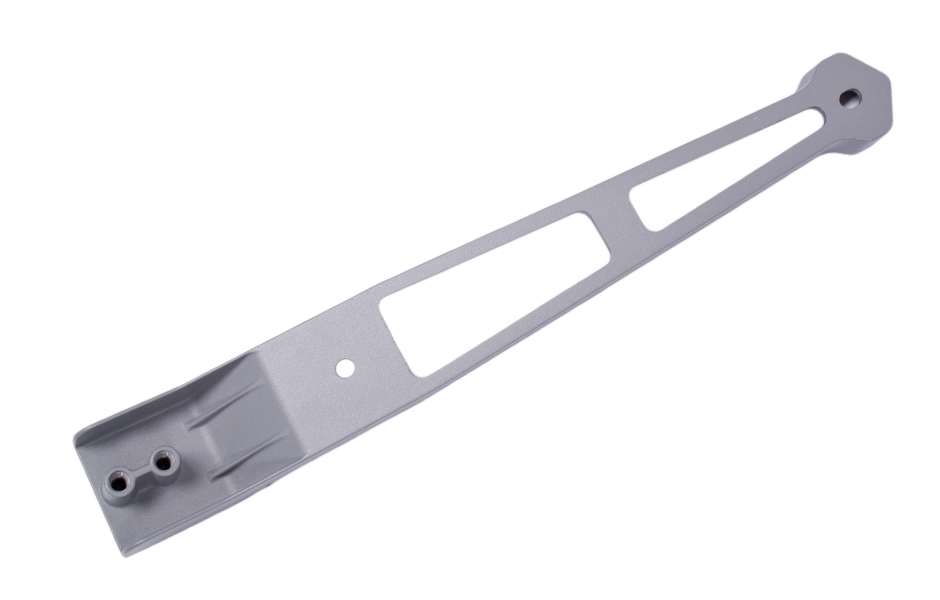

Serv-All works hard developing, maintaining, and constantly improving our quality edge in all our manufacturing and business processes: from initial order to final delivery. We strive for quality with state-of-the-art technology as well as skilled craftsmanship. Serv-All reduces variation in the manufacturing process, which allows us to control costs and reduce rejects. We also drive improvement through problem solving projects such as lean activities, sampling, numerical evaluation of metrics, design of experiments, and variation studies. Our quality systems promote proactive defect prevention rather than reactive defect detection throughout the entire corporation.

Quality assurance methods:

- Quality system management, auditing, and engineering

- Advanced problem solving methodologies (including Six Sigma)

- Following APQP, control plans, FMEA, MSA and PPAP guidelines

- CMM technology

- SPC (Statistical process control), GR&R (Gage reproducibility and repeatability), GD&T (Geometric dimensioning and tolerance), capability studies and other critical inspection monitoring practices

- ISO 9001:2008

- Alloy certification

Our advanced precision inspection and testing abilities cover a range of dimensional and functional product requirements and specifications. These capabilities support comprehensive inspection actions ranging from receiving to final audit, as well as first article layouts, full AIAG, PPAP and IQ, OQ, PQ Process Validation Submissions.

Quality Guiding Principles

- Quality comes first: To achieve customer satisfaction the quality of our products and services must be our number one priority.

- Customers are the focus of everything we do. Our work must be done with our customers in mind, providing better products than our competition.

- Continuous improvement is essential to our success. We must strive for excellence in everything we do: in our products, in their safety and value, our human relations, our competitiveness, and our profitability.

ISO 9001:2008 CERTIFIED

Serv-All quality systems place an emphasis on customer satisfaction. We focus on establishing the foundation for providing exceptional products that meet specifications and exceed our customer’s expectations. As a global manufacturing company and supplier, Serv-All is certified with the International Standards System, which means we continually align our manufacturing quality and organization at the highest levels.